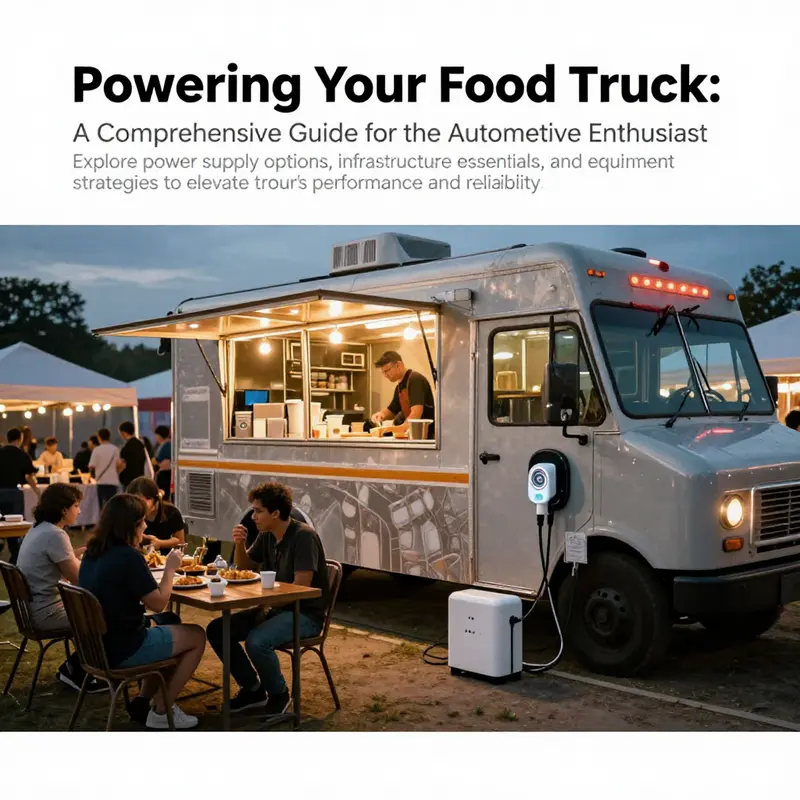

Powering a food truck effectively is not just a technical necessity; it’s an art that marries culinary ambition with mechanical prowess. For hobbyist car modifiers, professional tuners, and classic car restorers, understanding how to optimize power supply can be as thrilling as enhancing vehicle performance. This guide delves into effective power sources, ensuring safety in electrical infrastructure, and selecting energy-efficient equipment, all tailored for a premium mobile dining experience. In the following chapters, we’ll explore distinct power supply options, safety considerations in wiring and infrastructure, and the latest strategies for equipment selection and maintenance, all aimed at ensuring your food truck runs smoothly and efficiently.

null

null

Powering the Route: Crafting a Safe, Reliable Electrical Backbone for a Food Truck

Electric power is the quiet engine behind every sizzling grill, crisp freezer, and midnight glow of a food truck. It sits at the center of daily operations, quietly orchestrating the rhythm of service, the safety of staff, and the consistency of every customer experience. Designing an electrical system for a mobile kitchen is not simply about plugging devices into sockets; it is about building a resilient, adaptable heartbeat that can endure the bumps of the road, the unpredictability of locations, and the ebb and flow of demand. The most effective trucks treat power as an integrated system, where external grid access, on-board generation, and on-site renewable storage work in harmony rather than at cross purposes. When you approach power with that mindset, you gain not only reliability but flexibility, which is essential in a business that thrives on speed, quality, and location variety. A thoughtful electrical foundation keeps staff focused on cooking and service rather than chasing outages, and it offers a platform on which future upgrades—new appliances, more refrigeration, or expanded service hours—can be added without a total rethink of the core systems.

To begin, it helps to picture the truck’s electrical ecosystem as a dynamic network rather than a simple sum of watts. You will be juggling continuous loads—what keeps refrigerators, pumps, and lights running—and startup surges, which arrive when the compressor kick-starts, the microwave doors swing open, or the blender roars to life. The difference between running watts and peak startup power is not academic; it translates into the size and type of equipment you need, the kind of generator you select, and the safety margins you must bake into your plans. A careful lineup of all equipment used during peak operation—every pot, every fridge, every display panel—lets you estimate the minimum generator capacity necessary to avoid overloads and dropouts. For instance, a microwave may sit around 1,200 watts, a blender or mixer in the 500–1,000-watt range, and a POS system with lighting in the 300–500-watt band. When you total these together, you are not simply tallying a budget line; you are defining the nerve center of your kitchen on wheels.

The calculation matters not just for current needs but for future reliability. It should account for the fact that some devices draw more when they start than when they run. Refrigerators are a perennial source of startup surges because their compressors must overcome inertia and friction before settling into a stable operation. HVAC units behave similarly, and even a modest walk-in cooler can demand a hefty initial push. With this awareness, you can size for startup watts—often up to two or three times running watts for specific appliances—so the system never trips a breaker or drops critical loads. The result is a generator that has sufficient headroom to handle the kitchen’s tempo without constant cycling, reducing wear and tear and extending the life of the equipment.

Selecting the right generator becomes the next decisive step, and it is one that shapes both comfort and cost over time. Inverter generators have become a favorite in mobile kitchens for their quiet operation, clean power output, and superior fuel economy. They deliver a stable sine wave that is gentle on sensitive electronics like POS systems and digital displays, diminishing the risk of voltage fluctuations that can cause misreads or data loss at the register. The trade-off is that inverter units carry a premium price and may provide less raw peak power than some conventional models. Conventional generators, on the other hand, still attract operators who require high, affordable wattage for larger crews or very equipment-dense setups. They are robust but louder and generally less stable in terms of voltage regulation. The decision is rarely about “the best” in isolation; it is about matching the generator’s strengths to your menu, location, and hours. A large, busy truck in a high-traffic urban setting may justify the investment in an inverter-based system for its quiet operation and safer power quality, while a truck operating in remote locations might lean toward a conventional unit with a higher peak capacity, provided it is properly contained and managed for noise.

A holistic approach to power also means recognizing the value of a hybrid strategy that can ride out the uneven terrain of street vending. The most resilient setups combine external power when it is available, supplement with solar and battery storage during daylight hours, and rely on a diesel generator for nighttime service or peak demand. This triad can dramatically reduce fuel costs and emissions while delivering uninterrupted service across shifting venues. In practical terms, you might connect to a grid outlet at a market, run the essential lights and refrigeration on solar-charged batteries during the day’s lull, and reserve the high-wattage operations for after dark when the generator takes the load. The beauty of this approach is not merely environmental; it is economic. It allows you to scale operations without exposing your business to the volatility of fuel prices and grid outages. The sun becomes a partner in your daily rhythm, offsetting energy draw and lowering generator runtime during predictable daylight hours.

Solar power and battery storage deserve a careful, non-dogmatic treatment. Solar panels on the roof can trickle charge auxiliary batteries, which in turn feed a portion of the onboard load through an efficient inverter. That energy is most impactful for lighting, POS displays, fans, and small appliances. The caveat is that solar, by itself, rarely suffices for high-demand cooking operations, especially in long-shift days or busy events. Yet when paired with a well-designed battery bank and a smart charge controller, solar can meaningfully reduce the generator’s run time, extend the life of the generator, and cut fuel costs. The battery system, in turn, must be managed with a robust Battery Management System (BMS). A BMS protects lithium-ion or other rechargeable packs from overcharging or deep discharge, and it monitors temperature to prevent thermal runaway. It can balance cells, optimize charging cycles, and provide health diagnostics that alert you to aging packs before a failure occurs. The role of monitoring tools cannot be overstated here. A reliable battery monitor gives you real-time visibility into voltage, current, and state of charge, and it can flag when a bank is approaching its limits.

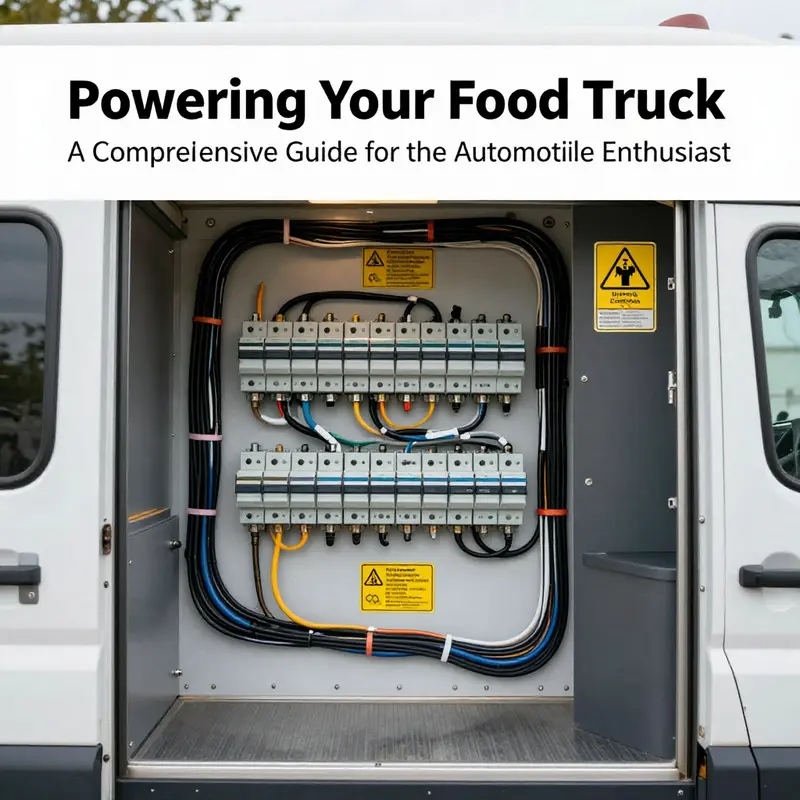

Beyond power generation, the electrical infrastructure itself must be engineered to protect people and equipment. Proper wiring and circuit protection form the backbone of safety. This means professionally installed circuits with appropriate breakers and fuses, careful grounding, and adherence to local codes. Outdoor operation, weather exposure, and the vibrations of road travel place unique stresses on conduits and connections. Weatherproof, industrial-grade outlets and weatherproof cabling rated for high currents become non-negotiables, not afterthoughts. A dedicated distribution panel should centralize the loads, with clearly labeled circuits for refrigeration, cooking, lighting, and electronics. For any system that uses multiple power sources, a thoughtful switching or automated transfer approach helps prevent backfeeds and ensures a clean transition from one power source to another. The complexity is not unnecessary; it is a practical safeguard that reduces the risk of electrical faults that could endanger staff or customers.

If your power strategy includes battery storage and solar, a careful emphasis on battery health becomes essential. The BMS protects the batteries from overcharging, deep discharging, and thermal conditions. It also communicates with the inverter to ensure stable, clean power delivery. When you add an onboard generator to the mix, you must also account for fuel storage, ventilation, and safe-exhaust management within a compact compartment. The safety protocol should extend to fueling procedures, container handling, and spill prevention. Even the orientation of the generator matters; it should be mounted with vibration-dampening materials to reduce wear and to minimize noise transmission into the living and dining areas of the truck. Grounding is not a luxury but a safety-critical feature. Grounding and bonding prevent electric shocks, equipment damage, and electromagnetic interference that can affect sensitive electronics. The entire system should be designed with a clear, documented maintenance plan that includes regular oil changes, filter replacements, battery checks, inverter tests, and a periodic review of wiring and conduit integrity.

The practicalities of installation invite a careful, almost architectural perspective. Mounting the generator in a dedicated, ventilated compartment, with ample clearance for heat dissipation, is vital not only for performance but for longevity. The layout should minimize the distance between power sources and the loads they serve to reduce voltage drop and wiring losses. Wiring should follow recognized standards, with weatherproof conduit, proper gauge conductors, and robust strain relief to withstand the jostling of travel. A properly sized switchgear or transfer switch ensures that when you plug into external power, the truck’s onboard circuits don’t feed back into a power source and cause a hazard or regulatory violation. The question of fuel storage demands disciplined handling: approved, clearly labeled containers, secure mounting, and excellent ventilation in the generator compartment prevent fumes from accumulating and reduce the risk of accidents. Maintenance routines should be predictable and thorough. Oil changes, air and fuel filter replacements, battery checks, and inverter calibration are not chores to postpone; they are investments in reliability that keep the operation steady through peak hours and variable sites.

As operators expand or refine their fleets, the debate about alternates to fossil-fueled power grows more common. Electric food trucks—where battery systems drive the entire kitchen, charged by solar or the grid—represent a compelling, low-emission direction for ambitious businesses. These vehicles rely on highly efficient, purpose-built appliances and an electric drivetrain that can be tuned for quiet operation in crowded markets or near residential zones. They require specialized training for the crew, particularly around battery life, charging schedules, and onboard system diagnostics. The shift toward electrification is not a mere trend; it reflects a broader commitment to sustainability, which aligns well with urban audiences that value environmentally conscious brands. Still, this path demands upfront investment, meticulous engineering, and a longer planning horizon to ensure that reliability remains uncompromised when the truck is busy and miles away from a service station.

Compliance and maintenance form the final, ongoing obligations of any prudent operator. Local regulations around electrical safety, noise restrictions for generators, and environmental impact require attention and regular review. Even the best-designed system can fail if not maintained; the rules of the road, literally and figuratively, demand a schedule of inspections, performance tests, and component replacements aligned with manufacturer recommendations and local codes. A continuous improvement mindset—documenting lessons learned from each event, updating load calculations, and validating new equipment against the existing electrical backbone—keeps the operation resilient as it grows. In practice, the most successful trucks treat power as a living system: it evolves with the menu, shifts with the seasons, and adapts to new venues. A well-documented maintenance log, an up-to-date electrical schematic, and a clear protocol for dealing with outages are not burdens; they are the guardrails that keep operations smooth, safe, and scalable. For operators who want a structured reference to align compliance with startup realities, the community and industry literature offer practical pathways, including resources that discuss the broader regulatory frame and safety expectations as part of a responsible business plan. To explore a closely related dimension of startup considerations, many operators also consult internal guides on legal considerations for Latino food truck startups legal-considerations-latino-food-truck-startups.

When the day’s service ends and the truck returns to the yard or to a partner site, a disciplined approach to inspection, testing, and planning becomes a competitive differentiator. The most reliable fleets run through a mental checklist that doubles as a planning tool: have you verified the integrity of all connections, ensured the battery state of charge is adequate for the next shift, and confirmed that the transfer switch is ready for quick, safe operation? Are the safety labels intact and legible? Is there a clear path for refueling, venting, and cooling to prevent overheating? Do you have a plan for weather-related contingencies, such as rain, high humidity, or salt from coastal operations? These questions are not about micromanagement; they are about safeguarding a business that depends on a consistent, predictable supply of power under the most demanding conditions. The same questions guide the continuous optimization of the system: as you add more refrigeration or as a new line of high-watthungry equipment approaches, you revisit your load calculations, re-check the generator’s capability, and consider whether a solar-topped battery bank warrants drawing down less on the generator at peak times. Each revision improves reliability, reduces risk, and maintains the confidence of customers who expect reliability as the baseline, not the exception.

For readers seeking a practical, field-tested reference on generator sizing, noise management, and system integration, there are contemporary guides that translate theory into action. A reliable external resource offers a clear, hands-on perspective on selecting and implementing essential generator systems for mobile kitchens, including how to balance engine-driven outputs with solar input and battery storage. This material complements the in-truck considerations and helps align practice with the evolving landscape of mobile food power solutions.

In summary, powering a food truck is less about a single device and more about a resilient, integrated ecosystem. It requires precise load estimation, thoughtful choice of generation technology, and a disciplined approach to safety, compliance, and maintenance. A hybrid model that leverages grid power when available, solar charging during daylight, and a generator for peak or remote operation can deliver reliable performance while controlling costs and emissions. The core ideas—anticipate startup surges, protect sensitive electronics, and plan for a future that may include battery-dominant operation—anchor a design that is as adaptable as it is robust. The result is a power system that supports the craft of cooking, the efficiency of service, and the ambition of growth, all while keeping staff safe and customers satisfied. For further reading on generator systems and best practices for mobile power solutions, explore the external resource linked above and consider how it might inform a tailored, site-specific configuration for your own kitchen on wheels.

Powering a Mobile Kitchen with Precision: Building a Resilient, Efficient Electrical System

Powering a food truck is less about finding a single, perfect power source and more about weaving a reliable, adaptable electrical tapestry that can support high-demand cooking, cold storage, lighting, and customer-facing technology without breaking the bank or the rhythm of service. The best operators treat power not as a backdrop but as a core business asset. They begin with a clear picture of what their unit must sustain throughout a shift, then translate that picture into a practical, layered system: a chief power source, complementary supports, and a disciplined maintenance routine that keeps everything humming. The logic guiding this approach is straightforward, even if the math can feel intricate. You start by understanding your total power requirements, then you align those needs with a hybrid strategy that leverages the strengths of grid connection, on-board generation, battery storage, and renewable energy. The aim is to reduce fuel consumption and emissions where possible while preserving uptime during peak service periods and at remote events. In this sense, power becomes a design constraint that shapes equipment choices, layout, and daily operations, not a bolt-on afterthought.

The first pillar is a realistic assessment of power demand. Many operators focus solely on running watts—the continuous load that keeps a blender spinning, a refrigerator cooling, or a grill heating—but the most consequential part of the equation is surge watts. Motors in compressors, refrigeration units, and HVAC fans throw a temporary but substantial wattage spike as they start up. A microwave, for example, might run comfortably at around 1,200 watts, but its startup could briefly push well beyond that. The same logic applies to a high-end blender, a large ice maker, or a hot-water boiler. When you add lighting, POS systems, and a small control computer to monitor temperatures and inventory, the total picture becomes more complex than a simple sum of running watts. The discipline is to document both continuous and startup loads for each piece of equipment, then to build a safety margin into the generator capacity and the battery/inverter sizing. A practical rule of thumb is to design for the worst combination of startup surges you expect over a typical service window plus a buffer for contingencies such as a clogged line or a sudden demand spike when a new batch hits the steam table. This mindset steels the operation against brownouts, voltage drops, or unexpected shutdowns that corral a busy service into a nightmare of lost sales and stressed staff.

To translate this into a workable plan, operators should inventory every major appliance and peripheral: induction cooktops, fryers, griddles, microwaves, blenders, mixers, reach-ins and undercounter refrigerators, a warming cabinet or hotter, dishwashing or sanitizing equipment, a POS terminal, cash drawer, lighting, fans, and the essential fans or HVAC components that might be used during a warm summer day to keep staff comfortable. Each item has a nominal running wattage and, critically, a startup spur. The sum of continuous loads sets a baseline; the highest startup combination defines the peak the system must tolerate without tripping breakers or compromising performance. The real-world takeaway is that a well-dimensioned system is more forgiving of transient demands than a lean one that merely covers the day-to-day load. In practice, operators often discover that their needs evolve with the season, the event calendar, and the menu mix. A truck that serves frozen treats during summer, for example, suddenly adds air-curtain cooling and a more demanding refrigeration profile in the back of the house when peak heat drives more stock through the cooler.

With the load profile established, the next phase is choosing an infrastructure that is robust yet flexible. A mature approach blends three layers: a dependable external power source when available, onboard energy storage to sustain operations between grid connections or off-grid periods, and an energy-dense generator to cover the long hours of service and peak demand. The external power connection, typically a standard 120V or 240V supply at a site or event, is the simplest and most stable option for days when the truck can plug in. It allows the full use of high-wattage equipment—grills, fryers, and refrigeration—without draining a battery bank. The flip side is that not every site offers reliable grid access, and even when it does, the cost or the risk of a power outage may push operators to keep a back-up strategy ready.

Onboard generation enters the conversation not as a single, monolithic power source but as a flexible partner that can operate in tandem with the grid or independently. This includes portable or installed diesel or gasoline generators designed to deliver sustained power for lengthy operations. Generators shine when the truck parks in remote locations, at large events without reliable electrical infrastructure, or during late hours when the grid connection is not an option. Crucially, the best practice is to select a generator with the right balance of wattage, fuel efficiency, endurance, and maintenance simplicity. A unit that is loud, fuel-hungry, or difficult to service narrows the window of profitability and can sour customer experience, especially in urban settings where noise restrictions matter.

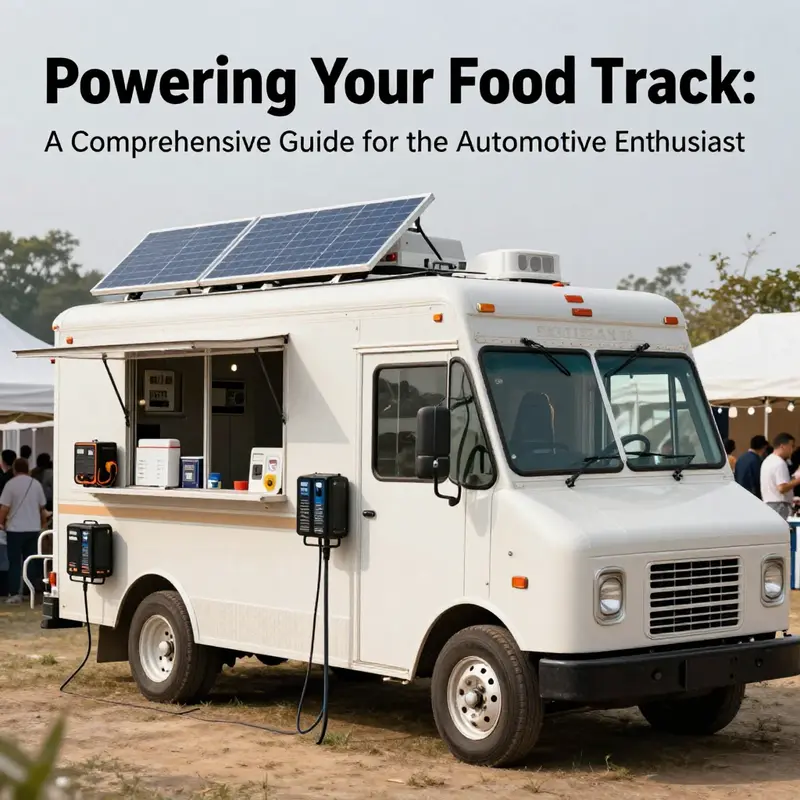

The third layer, solar power, has moved from novelty to capability for mobile operations. A roof-mounted solar array paired with a battery bank can dramatically cut fuel costs and emissions by providing daylight charging for lights, small appliances, and battery health. Solar alone rarely powers heavy cooking loads, but it pays back quickly by reducing draw from other sources during daylight and by extending the life of battery storage by maintaining a healthier state of charge. The upside of solar is not only the energy but the resilience style it brings: a sun-filled shift reduces reliance on diesel and protects margins during peak rate times or fuel price spikes. The trade-offs are space (roof area for panels), initial cost, and the need for a smart charge-control strategy that protects the health of lithium-ion or other chemistries and coordinates charging with in-use loads.

This triad—grid, solar, and storage—also dovetails with a vehicle’s inherent electrical architecture. Modern trucks often already include a vehicle battery and a dedicated inverter designed to power low-wattage devices in idle or while parked. This is a useful buffer, but it should not be treated as a primary source for kitchen appliances because vehicle alternators and standard 12V inverters are not optimized for constant, high-wattage loads. Instead, the system should be layered so that the vehicle’s battery powers incidental devices and lighting, while the heavy culinary and refrigeration loads ride on a purpose-built power network with its own battery bank and a sophisticated charge controller. A comprehensive answer to reliability is not about one big battery but about how multiple energy sources can be managed to maintain a consistent voltage, preserve battery health, and minimize fuel consumption.

The electrical backbone of a mobile kitchen must also be engineered with safety and longevity in mind. The wiring should be professionally installed with appropriately rated breakers, fuses, and grounding. Heavy-duty, weatherproof outlets and cabling designed for outdoor use are not optional details but essential protections against shock, short circuits, and heat buildup. A battery management system (BMS) becomes indispensable whenever multiple batteries, high-capacity inverters, and solar charging are in play. A BMS monitors state-of-charge, prevents overcharging and deep discharge, and manages thermal conditions. In a kitchen environment where hot cabinets, compressors, and fast-moving fans run for hours, thermal management is not just about comfort; it’s about preserving battery life and avoiding runaway conditions that can escalate into safety issues.

The equipment itself matters—selecting energy-efficient, commercial-grade appliances designed for mobile use is a practical way to tame the load. Induction cooktops, in particular, stand out. They deliver precise temperature control, high energy conversion efficiency, and a smaller heat footprint relative to gas or older electric stoves. Their reduced energy draw aligns well with battery storage and solar charging, especially in daytime operation with a partial grid connection. Dual-voltage appliances that operate on both AC and DC can provide extra flexibility when you want to run certain devices directly from a battery bank without needing an inverter for every accessory. The objective is not to chase novelty but to align the menu, service cadence, and the electrical profile to a consistent, sustainable energy footprint. A practical outcome is that a menu designed with an eye toward efficiency—shared cooking zones, rapid heat transfer, and multi-use equipment—reduces peak loads and smooths the demand curve across a shift.

Another layer of strategy concerns the orchestration of energy during service. A hybrid approach—where you use external power where available, draw down solar-charged batteries during daylight, and rely on a diesel generator during night hours or when demand spikes—offers a straightforward path to reliability. This model reduces fuel costs and emissions while protecting the customer experience from outages caused by grid instability or generator fatigue. It also opens up operational planning: you can time heavy cooking tasks to daylight hours when solar charging is at its strongest, then switch to a generator in the cooler evening hours as the demand pattern shifts toward refrigeration and point-of-sale processing. The practical upshot is a smoother workflow, less stress on staff, and more consistent service quality across diverse locations and events.

Maintenance is the thread that ties this system together. A power system in a food truck lives and breathes through regular, disciplined care. It starts with routine checks—oil levels in any generator, air filters, spark plugs, and fuel lines—with a weekly or biweekly cadence that fits the service schedule. But maintenance should also be proactive: periodic load testing under real-world conditions, not merely a no-load idle check. This is how you identify equipment that strains under peak loads, reveals deteriorating battery capacity, and surfaces connection issues before they become failures during a busy service. A log of maintenance activities becomes a living document, a memory of how the truck has aged and how that aging is being managed. In an era of smart devices, a monitoring system that alerts you to low fuel, overheating, or unstable voltages can save downtime and extend the life of the entire system. The goal is uptime—every minute that you are cooking, chilling, and serving is money, and the cost of downtime dwarfs the expense of a well-run maintenance regime.

The human element should not be overlooked in this technical tapestry. The most robust power system is only as good as the people who operate and maintain it. Staff should understand not just how to start a generator or switch between power sources, but how to read the system’s indicators, respond to a warning, and re-prioritize loads if a fault occurs. This is where training pays dividends: a quick, practiced routine for pulling down surge-prone devices, a standard sequence for switching between grid and generator, and a shared checklist for post-shift battery balancing. The better the crew understands the system, the faster they can adapt to changing conditions, such as a weather-driven swing in electrical demand or a last-minute menu item that adds a new load to the kitchen.

In a field where weather, sites, and customers shift daily, the resilience of a power system hinges on foresight and flexibility. The hybrid approach—grid when possible, solar plus storage during the daylight hours, and diesel for the demanding, fuel-intensive periods—works best when it aligns with a well-thought-out equipment mix and a disciplined maintenance program. The blend reduces idle fuel consumption, lowers emissions, and preserves performance in places where the generator might otherwise run for long stretches or where the grid may dip in reliability.

For operators seeking deeper context and broader market trends, industry analyses illuminate how mobile refrigeration and associated electrical systems are evolving. Manufacturers and operators increasingly integrate engine-driven alternators, dedicated diesel generators, and grid-connected configurations to meet the dual demands of mobility and reliability. This broader perspective underlines a practical reality: power for a food truck is not static. It evolves with fleet size, menu complexity, and the specific event ecology your business targets. A mature operator treats electrification as an ongoing optimization project rather than a one-time setup. They adjust component sizing as the business grows, refine load management strategies, and continually invest in better monitoring and maintenance to protect uptime and service quality.

As you design or retrofit a truck, there is value in looking beyond your own kitchen to the wider ecosystem of mobile food services. You may find insights in profiles of veteran operators who have learned to balance speed, reliability, and efficiency in high-pressure environments. These practical lessons—such as staggering peak loads, allocating power budgets for new equipment, and coordinating solar charging with service cycles—are the kind of tacit knowledge that often separates successful ventures from ones that stumble under power constraints. For readers who want to see such practitioner perspectives, the following resource offers a window into the experiences of seasoned operators: Profiles of Veteran Food Truck Owners. This reference reinforces that the art of powering a mobile kitchen is as much about disciplined operation and adaptive learning as it is about hardware.

The bottom line is simple in concept, but its execution requires care and foresight. Build your system around a precise understanding of continuous and startup loads, choose equipment that is efficient and compatible with your energy strategy, and design a layered power network that can switch seamlessly between grid, solar, and fuel-powered sources. Pair that with a robust electrical infrastructure, professional installation, and a rigorous maintenance discipline, and you create a business that can reliably feed customers no matter where the truck parks. The payoff is measurable: steadier service, lower operating costs over time, and the confidence to take your menu to new locations without being hostage to a single power source. In the end, powering a food truck is a practice in balancing abundance and restraint—selecting the right tools, deploying them thoughtfully, and maintaining them with a regimen that honors both safety and uptime. The result is a kitchen on wheels that can improvise, endure, and flourish in the dynamic world of mobile food service.

External Resource: For a broader, market-focused view on how mobile refrigeration and related electrical systems are evolving in the road transport sector, see the Road Transport Refrigeration Equipment Market report by Fortune Business Insights, which discusses engine-driven alternators, dedicated diesel generators, and grid-connected systems as part of larger energy strategies for mobile food service. https://www.fortunebusinessinsights.com/industry-reports/road-transport-refrigeration-equipment-market-101976

Final thoughts

In navigating the world of food truck electrification, enthusiasts can harness their passion for automotive performance to ensure outstanding culinary ventures. By understanding diverse power supply options, prioritizing safety in electrical infrastructure, and selecting energy-efficient equipment, food truck operators can enhance their operations while minimizing costs and environmental impact. Whether you’re a hobbyist looking to customize a mobile kitchen or a professional seeking reliable solutions, this guide provides the foundation for a reliable and impressive food truck experience. Remember, the journey of powering your food truck is as vital as the culinary creations that emerge from it.